The SuRBe group work with material manufacturers, building contractors and other stakeholders involved in developing innovative systems for building fabric whether at the component or building level – predominantly using natural materials.

Prefabricated Building Fabric – Timber

Combining expertise in architectural engineering and technology, building control surveying, with product design and manufacturing management, the SuRBe team are advising timber frame organisations, housing associations, architects and building contractors on developing and refining offsite manufactured and prefabricated timber frame systems. This is in order to improve product lines, implement more ecological materials and also increase the use of home grown timber from the UK and Wales for high quality and healthy homes.

A number of projects have been/continue to be associated with this work:

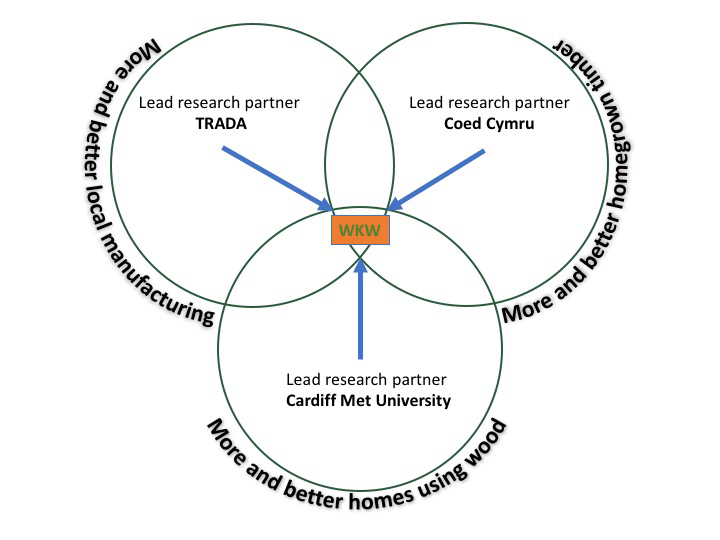

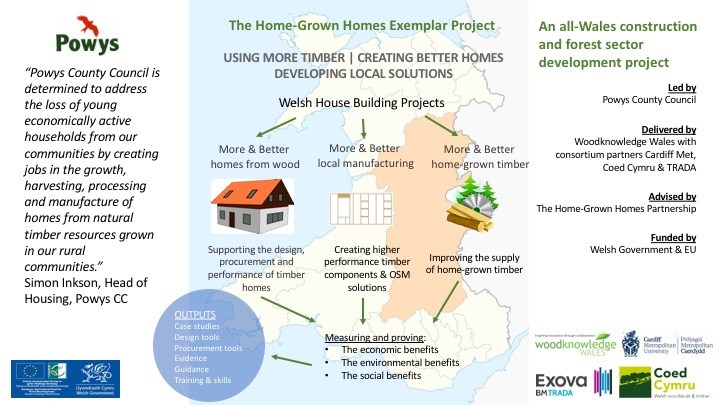

2018-2021 Home Grown Homes RDP for Powys County Council to spearhead the investigation of the challenges and solution for increasing the construction of high performance and high quality and healthy homes from UK and Wales grown timber. The project is led by Woodknowledge wales, and in collaboration with Exova Trada and also Coed Cymru. The SuRBe group bring expertise in architectural technology, building performance evaluation and environmental public health, and are leading one of three work packages, entitled More and Better Homes from Wood. Activities involve review of architectural and manufacturing detailing. Dr Littlewood will lead the implementation of a range of his diagnostic protocols including in-construction testing and Building Fire Safety Protection & Resistance Testing, Measurement and Reporting (BFS&R) process to test, measure and report on thermal, acoustic and fire (TAF) performance; across the construction/manufacturing phases of a range of case studies in Wales. See Dr Littlewood’s presentation from WoodBuild 2018.

2018-2021 A KESS2 project in collaboration with Woodknowledge wales, to develop and Validating Systemised Offsite Manufactured and Engineered Timber Dwelling Typologies from Welsh and UK Forestry Supply Chains for Increased Building Performance and Enabling the Transition to Nearly Zero Carbon Homes in Wales.

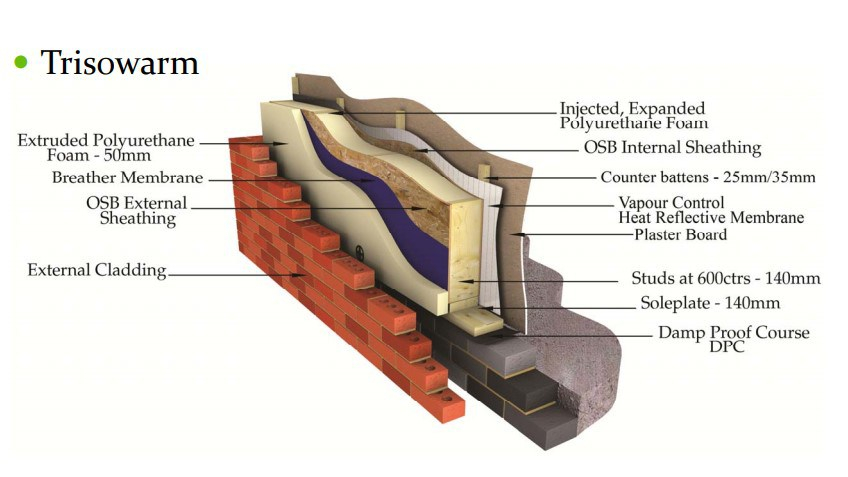

2019-2022, A three year KTP in collaboration and co-funded with and by JG Hale Construction/So Modular, InnovateUK and he Welsh Government. So Modular as part of Hale have developed a BBA certified timber closed panel for exterior walls (Trisowarm). The project will embed a Hale Innovation Management System (HiMS), with a Holistic Feedback & Optimisation Loop (HFOL) for transparent cost appraisal/reduction, and product performance enhancement (golden threads). Pioneering expansion of prefabricated components and transitioning into modular construction. Focused on their Trisowarm system for walls, expand to ceilings, floors, roofs.

Natural Materials – Rammed Earth

Paul Marais, an architect and Professional Doctorate student studying a Doctorate in Ecological Building Practices (D.EBP) at Cardiff School of Art and Design (CSAD), has won a prestigious South African National Award for Sustainable Design. Paul works and lives in South Africa, where he runs his own architectural practice specialising in a variety of work from urban design to tiny cottages.

Paul’s winning design, Otto Cottage in Botswana , was submitted by one of his clients and won the AfriSam-SAIA Award for Sustainable Architecture + Innovation. The award recognises contributions that bring sustainable innovation to living environments through an integrated approach to communities, planning, design, architecture, building practice, and natural systems and technology.

Otto Cottage is hand-made using natural materials comprised of rammed earth from the construction site, timber and locally harvested reeds; dramatically decreasing the carbon footprint of the construction process. Paul’s ecological design for Otto Cottage also includes using water from a nearby river in order to help ‘free’ cool the house through a series of external water features.

Paul said: “I enjoyed designing and building Otto cottage tremendously. I really enjoy natural building techniques, as opposed to conventional building because of the creative freedom it allows and the fact that the building is not harmful to mankind or the planet and its ecosystem and resources.”

Dr John Littlewood, Paul’s director of studies commented “Congratulations to Paul on his ecological approach to design and construction of affordable dwellings in South Africa. He has put in plenty of effort to raise the awareness of rammed earth construction in South Africa.”

Professor George Karani, Paul’s second supervisor from Cardiff School of Health Sciences said: “I am honoured to play a part in guiding Paul through the process of changing housing construction practice and people’s opinions in South Africa.”

References